+86 15959271231

+86 15959271231 sophie@cnrollforming.com

sophie@cnrollforming.com

+86 15959271231

+86 15959271231 sophie@cnrollforming.com

sophie@cnrollforming.com

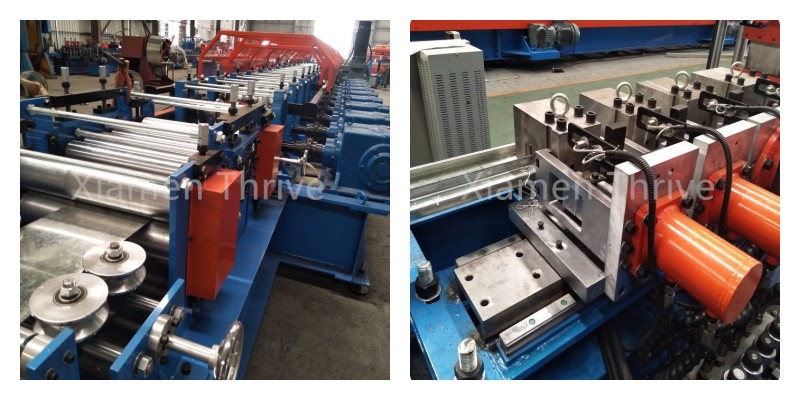

| Parameters | Specification |

| Voltage | 380V/50HZ/3PH or customized |

| Driving Motor | 45KW |

| Hydraulic Press/Cutting Motor | 7.5KW |

| Forming Steps | 20 stations |

| Working Speed | 15-25m/min (without punching and cutting action speed) |

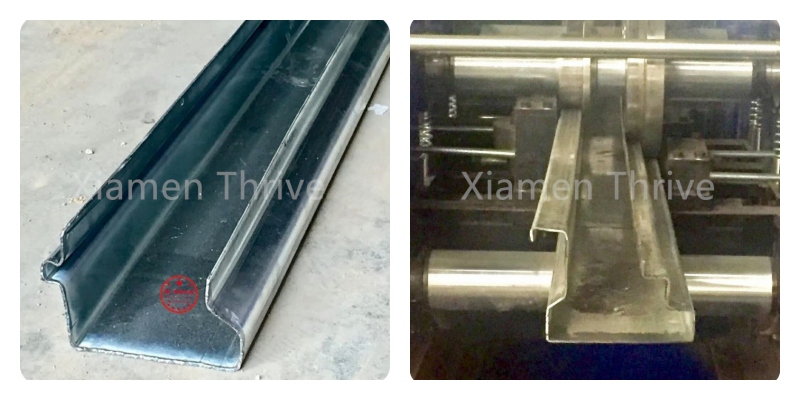

| Suitable Material | cold rolled steel, hot dip galvanized steel |

| Straightening rolls | 9 rolls |

| Leading Rollers Type | Manual |

| Thickness for Steel | 2-4mm |

| Shaft Diameter | 75/90mm |

| Shaft Material | High grade 45# forged steel |

| Roller Material | 45# steel with polished and heat treatment |

| PLC Cabinet | Schneider, Mitsubishi or Delta |

| Encoder | Omron |

| Sprocket Wheel | 45 steel high-frequencies quench |

| Cutting Blade Material | Cr12 steel |

| Machine Frame Material | Fine welded structural steel; |

| Roofing Material | PPGI, GI steel G245-345 |

| Painted Color | Blue+Gray White Or Customization |

| Overall Size | 10800*1600*1600mm |

| Weight | 13000KGS |

Metal House Frame Roll Forming Machine Components

5 Tons*600mm Hydraulic Un-coiler