+86 15959271231

+86 15959271231 sophie@cnrollforming.com

sophie@cnrollforming.com

+86 15959271231

+86 15959271231 sophie@cnrollforming.com

sophie@cnrollforming.com

| Parameters | Specification |

| Voltage | 380V/50HZ/3PH or customized |

| Driving Motor | 22KW |

| Hydraulic Press/Cuting Motor | 7.5KW |

| Forming Steps | 20 stations |

| Working Speed | 18-25m/min (without punching and cutting action speed) |

| Suitable Material | cold rolled steel, hot dip galvanized steel |

| Straightening rolls | 7 rolls |

| Leading Rollers Type | Manual |

| Thickness for Steel | 1.5-3mm |

| Shaft Diameter | 75/90mm |

| Shaft Material | High grade 45# forged steel |

| Roller Material | 45# steel with polished and heat treatment |

| PLC Cabinet | Schneider, Mitsubishi or Delta |

| Encoder | Omron |

| Sprocket Wheel | 45 steel high-frequencies quench |

| Cutting Blade Material | Cr12 steel |

| Machine Frame Material | Fine welded structural steel; |

| Roofing Material | PPGI, GI steel G245-345 |

| Painted Color | Blue+Gray White Or Customization |

| Overall Size | 9800*1600*1600mm |

| Weight | 13000KGS |

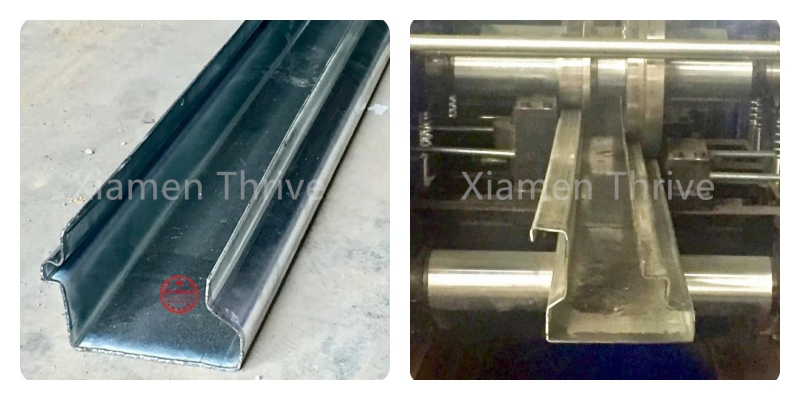

Machine Features

The container house frame roll forming machine is the popular designs for quick installation job site apartment for workers, so it is the good choice for the company who is doing this range business. The steel coil thickness is from 2mm to 3mm, considering to support the house roof and make whole container house more durable, we have leaded to improve the house frame roll forming machine profile design several times.